Product Portfolio

Bearings

We engineer products to comply with ISO standards while meeting your specific requirements.

Below are examples of solutions we can provide:

- Space Constraints

Custom designs for applications where standard components cannot be installed - Weight Reduction

Lightweight engineering without sacrificing durability - Cost Optimization

Performance-guaranteed designs with reduced production costs - Integrated Bearing Solutions

Manufacture a special bearing that combines a bearing with other parts

Wind Power Generation System

Featuring a vertical-axis wind turbine (VAWT), this system delivers rapid power generation

regardless of wind direction.

Compared to horizontal-axis wind turbines (propeller type), it operates with significantly

reduced noise and vibration, enabling installation in urban and residential areas.

Door Lock Mechanisms

We engineer and manufacture high-security door lock parts for diverse applications.

Please feel free to contact us regarding development and design including OEM

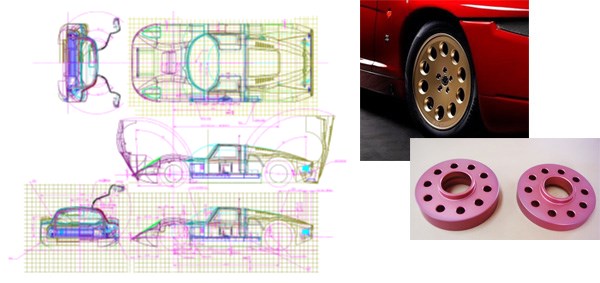

Automotive Applications

We specialize in developing high-performance automotive components. Our expertise

spans the entire process from concept to design, including magnesium forged wheels

(lighter than aluminum counterparts), aerospace-grade ultra-super duralumin wheel

spacers, and carbon fiber reinforced plastic (CFRP) components.

Labor-Saving Equipment/Device Development

We handle labor-saving equipment from the planning/design stages. For example, we

develop devices such as labor-saving equipment used in automotive maintenance that

can adjust the air pressure of multiple tires to the same level simultaneously

Development of a wheelchair lift system

Cost-effective installation compared to electric systems.

The rotating table design enables operation in compact spaces.

*Site-specific limitations may apply depending on installation environment.

Technology Introductions

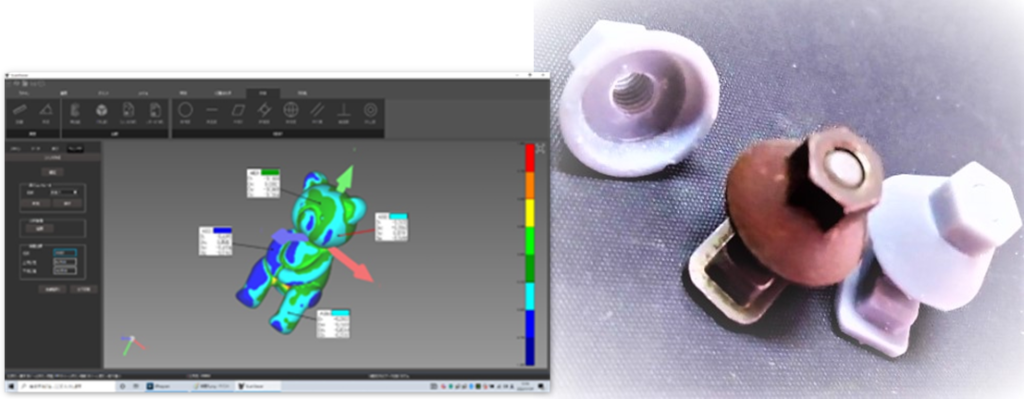

Application of 3D CAD, 3D

scanners, and 3D printers in

product development

We provide 3D modeling services for product

development, enabling comparison between

manufactured products and CAD data to verify

manufacturing accuracy.

For inquiries, please visit our "Contact Us" page—feel

free to reach out anytime.

Note: Projects involving industrial intellectual property

may require technical/legal evaluation prior to

acceptance.

Development of bearings aimed at weight reduction and smooth rotation

We have innovated bearing retainer technology by transitioning from traditional

metal designs to resin-based solutions, achieving dual objectives of weight

reduction and enhanced rotational smoothness.

Our geometrically optimized resin retainers represent a world-first configuration

in the industry. Building on this breakthrough, we further pioneered ceramic ball

integration within the system to push weight optimization boundaries.

Click here to see the rolling performance comparison video![]()

Development of Cup-and-Cone Bearings

The inner ring follows a deep groove ball bearing design, where the balls and

retainer remain integrated as a single unit during disassembly, simplifying

maintenance and reassembly.

Compared to standard deep groove ball bearings, this structure provides

enhanced thrust load capacity, making it ideal for applications with significant

thrust load demands.

Multi-Tire Pressure Sync Controller

Development of a system for simultaneous pressure equalization across two or more tires

Patent Registration: 6871488

Measurement Technology

Stringent Product Inspection Protocol

We develop tools and labor-saving devices for various products and

rigorously verify operational performance and structural integrity

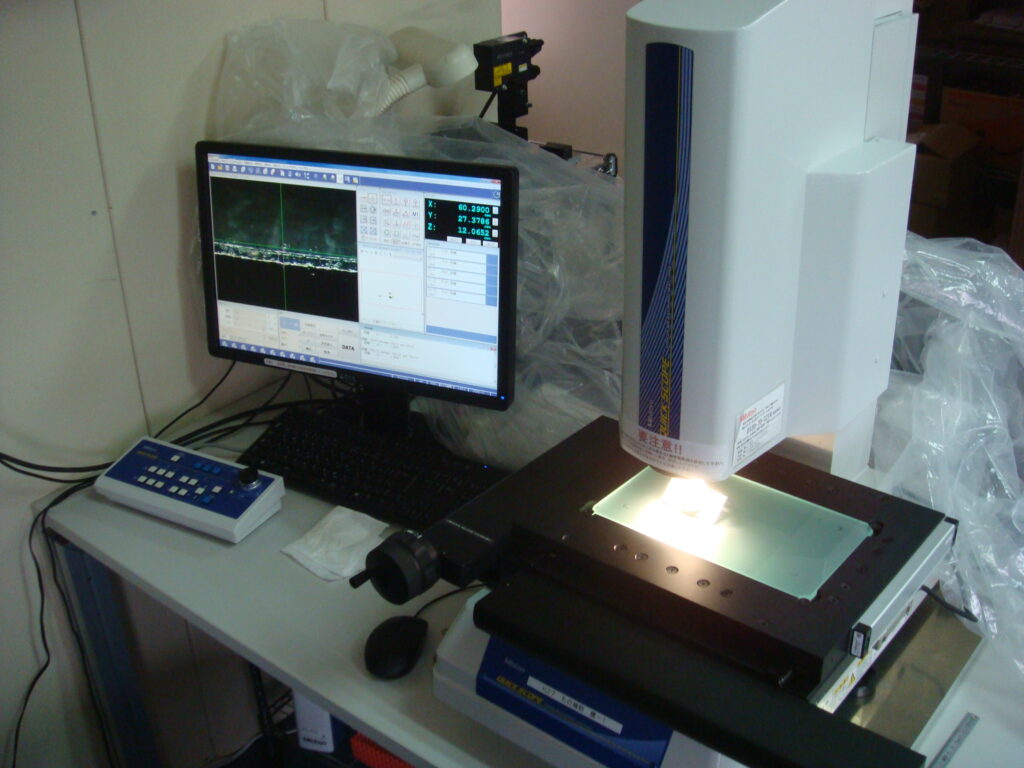

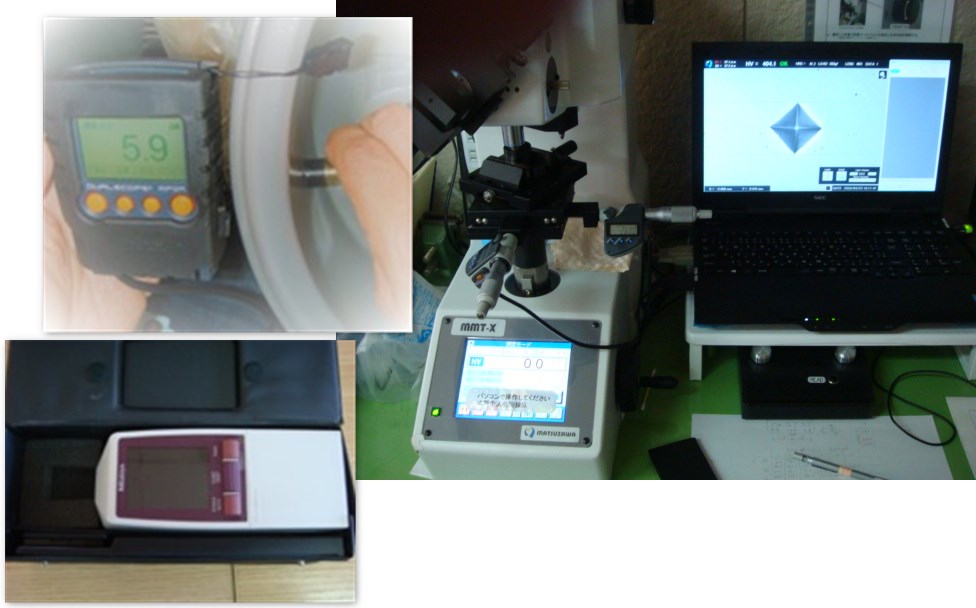

Image Processing Measuring Instruments

This is a precision image processing measuring instrument. It also

performs detailed inspections of products.

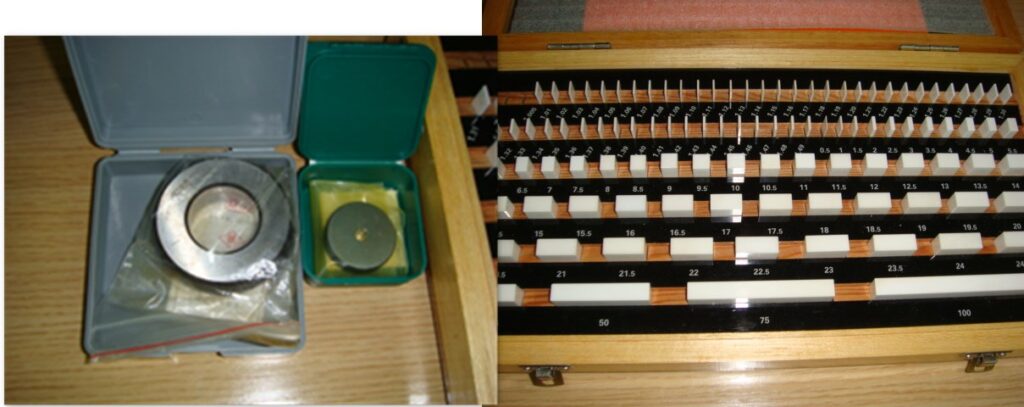

Our Dimensional Standard (Ceramic Block Gauge)

We have introduced ceramic block gauges, ring gauges, etc.,

unaffected by thermal effects, and established them as the

dimensional standards for various measurement instruments used inhouse.

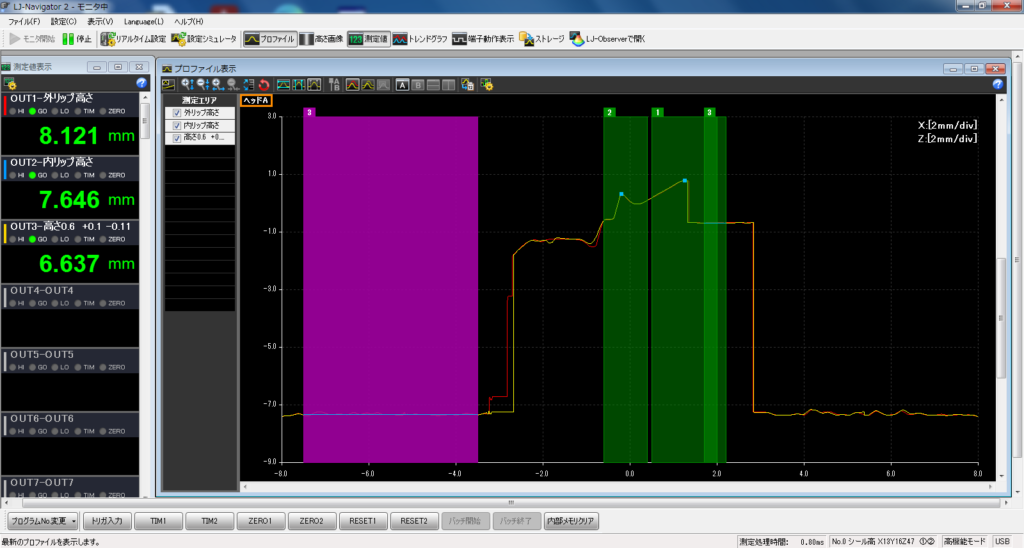

Laser Measuring Instruments

We use non-contact dimensional inspection to measure rubber

products and other soft materials

Hardness Testers ,Coating Thickness Gauges , Roughness Measuring

Instruments

We utilize precision instruments including: Hardness testers for measuring material

hardness, coating thickness gauges for verifying surface treatment layers and surface

roughness testers for finishing quality analysis

Testing Equipment for Various Product Evaluations

We test our products to meet industry standards and your specific needs. When standard

testing equipment isn't available, we design and build custom testing tools that follow

regulations to ensure reliable results

As outlined in our company introduction above, we also welcome inquiries regarding

component manufacturing services beyond 3D modeling.

If you have OEM/ODM product development projects or related projects, please contact

us via the“Contact Us‘ Section